NDS manufactures a flexible sandwich sheets containing of two steels or aluminums with a visco elastic layer in the middle to replace existing metal sheet. NDS efficiently dampens structure-borne sounds with little or no changes required for manufacture. NDS does not change the weight or structure of the existing product while performing sound damping function. This allows you to make effective sound damping at low cost without using additional damping material without causing additional weight and thickness in the structure.

NDS is used for a wide variety of applications such as automotive, ventilation, household appliance, transportation, shipbuilding industry.

NDS is produced with a visco elastic innerlayer specially formulated for a wide range of operating temperatures (-40 oC to 150 oC) in accordance with customer needs.

Shipbuilding Industry

NDS offers innovative solutions in the shipbuilding industry to reduce structure-borne noise, especially in areas with high noise sources such as engine room, technical room and generator room. Aluminum or steel sandwich panel is used as an acoustic decorative finishing panel, but can also be used as noise damping construction material in floors, walls, and machine construction.

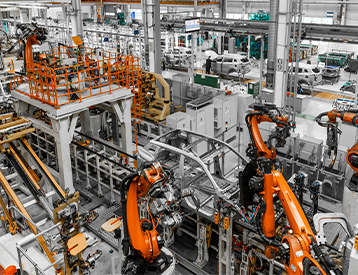

Industrial

NDS has experience of developing acoustic solutions for a great variation of industrial applications. We have been working closely with different industries from the very beginning to find the best solutions to acoustic problems and to meet the acoustic environment needs of our customers.

Transportation

A key issue in the control of noise inside vehicles is how to prevent or reduce the transmission or re-radiation of vibration as sound. NDS provides products and materials to solve undesired NVH problems in automotive, buses, subways, trucks, yachts etc.

NVH SOLUTIONS FOR CARS

NVH control is one of the major design objectives in today’s automobiles, since NVH affects ride quality, drivability and occupant comfort. Among the sources of noise and vibration are engine and powertrain vibrations, tail-pipe exhaust noise, high speed wind flow over and around the vehicle, tire imbalance, and tire rolling on the road surface. The principal source of harshness is the squeaks and rattles in the instrument panel, dashboard, and other interior components, some of which are caused due to sliding and bumping between poorly fitted or worn out parts. NVH control is achieved by reduction in noise and vibration at their sources (e.g., by using engine mounts or vibration isolators) as well as along their transmission paths that include body structure elements, body panels, and windows. Our solution is to produce damped metals. Our NDS panels have exceptional strength, flexibility and damping performance. NDS, consists of two layers of metal sheet with an vibration damping mid layer between them. Custom-made high vibration damping visco elastic adhesive is used fot that specific purpose. As the panel vibrate, the vibration energy is dissipated, thus the panel becomes a highly vibration and noise eliminating panel. The constrained layer sound damping steel (NDS) is more efficient than conventional vibration elimination solutions and a time saving , no mess, practical and easy apllication. NDS is also suitable for hygienic and dustproof production facilities as it eliminates peeling of over sheet applications and eliminates the possibility of dust pollution created by traditional insulation products.

DEFENSE INDUSTRY

We offer NVH solutions for defense industry vehicles. NDS and MDT provide high-end noise and sound dampening solutions in critical areas. We participate in the R&D studies of defense industry companies and carry out these studies by adhering to the principles of high sensitivity and confidentiality.

HVAC

NDS provide a very simple and cost effective soltion for the noise generated from HVAC, air conditioning, chiller and cooling tower plant. NDS uses the simplest solution is to introduce high-efficiency damping to the radiating surfaces to dissipate vibration energy to reduce the noise. This can be applied by replacing thin panels with laminated versions.

.png)